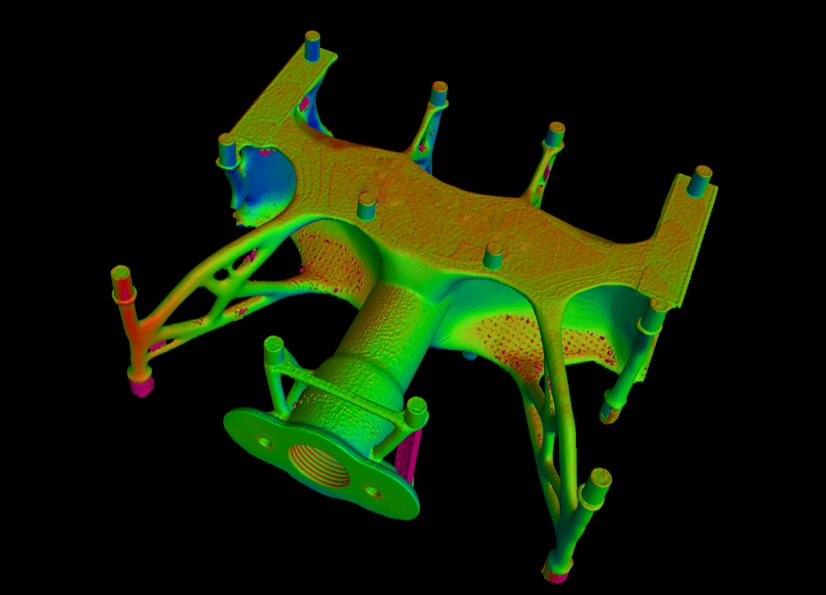

Additive Manufacturing

Motivation and aim:

Advancement of additive manufacturing processes through optimized process strategies, machine technology, factory integration and simulation for the targeted production of functionally integrated and individual components.

Materials and Processes

- Material extrusion

- Powder Bed Fusion

- Photopolymerisation

- Powder, slurry and feedstock development

Machine and process technology

- Material, component and process hybridization

- Component functionalization

- Real-time optimized, customized machine and production control

Integrative Process Chains

- Potential validation for series production

- End-to-end digitalization of the process chain

- Process chain and factory concept planning

Quality Control

- Scalable in-process manufacturing metrology

- Process capability studies

- Assistance systems

Contact:

Helena Wexel

Group Leader Additive Manufacturing

Group Leader Additive Manufacturing

76131 Karlsruhe

Kaiserstraße 12

Prof. Dr.-Ing. Frederik Zanger

Director Manufacturing and Materials Technology

Director Manufacturing and Materials Technology

Campus Süd

|

DFG FiberAdd Additive manufacturing of continuous fibre-reinforced polymer parts using the laser-sintering process |

Michael Baranowski M.Sc. Simon Zeidler M.Sc. Florian Kößler |

02.01.2024 - 31.07.2026 |