New junior research group "Dynamic quality control for the sustainable production of mobility solutions".

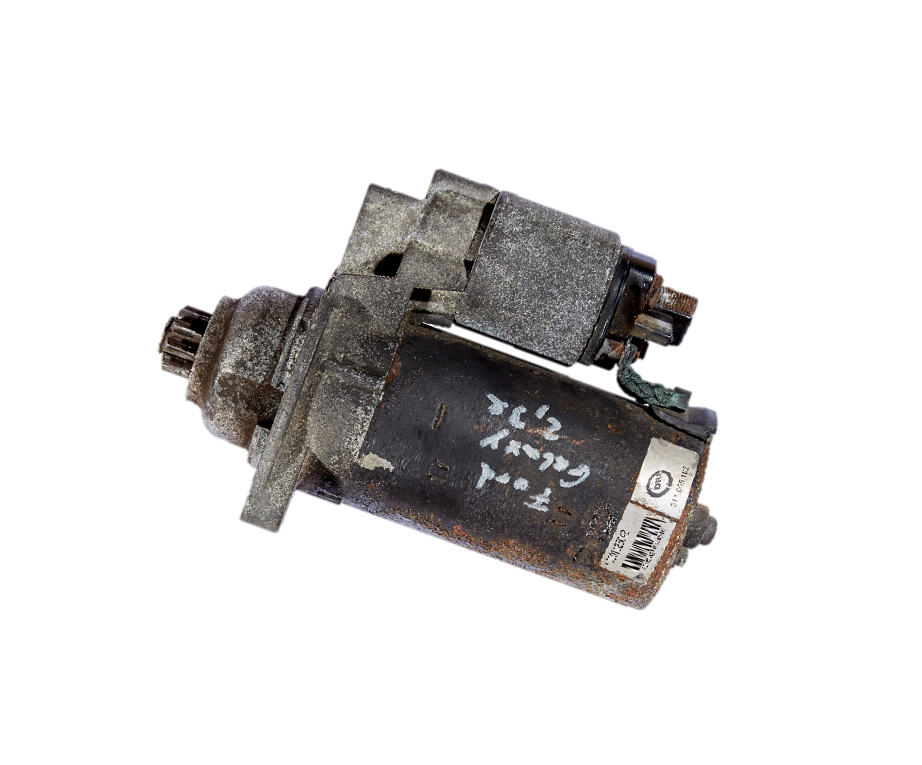

In the automotive industry in particular, a move away from the linear economic model toward a circular economy is necessary. A prerequisite for a circular economy is efficient closed-loop production. In this context, the junior research group looks at closed-loop production from material receipt to the finished product or to recycling. The focus is on restoring the quality of the discontinued product, which is particularly crucial for economic success. This requires intelligent quality control loops that regulate the remanufacturing processes based on the required quality characteristics.

The InnovationsCampus Mobility (ICM) has taken up this challenge and launched a junior research group "Dynamic Quality Control for the Sustainable Production of Mobility Solutions" in July.

Adaptive handling of unique products is the key

Every discontinued product is unique, i.e. one of a kind. Accordingly, each discontinued product must also be handled differently.

Fittingly, the junior group is looking at adaptive manufacturing in the form of remanufacturing or the production of spare parts and the use of standard spare parts. Performing further disassembly and transferring subsystems to recycling are also decision options. In all decisions, the reassembly of components in the control system must always be taken into account. As the basis of the quality controller, the junior research group is developing a digital product-production twin that uses data from tests and processes to create the necessary information base for an iterative and dynamic decision on the further steps of each individual component.

Due to the highly interdisciplinary nature of the task area, Florian Stamer considers exchange within the ICM with other junior research groups as well as with institutes at the Karlsruhe Institute of Technology (KIT) and the University of Stuttgart to be essential. Connectivity is also of great importance: here, valuable preliminary work can be drawn upon, but also the application for complementary or construction projects play an important role for Stamer. Here, further projects of the ICM, the EU and also national research projects are in his sights. In parallel, he exchanges ideas with representatives of industrial companies.