Veröffentlichungen

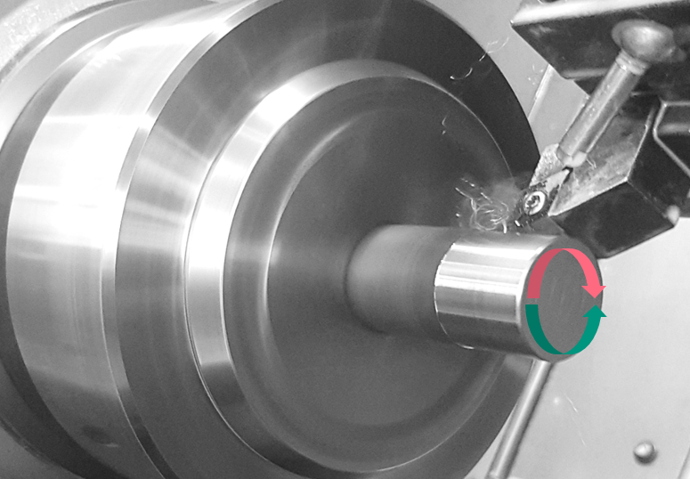

| [1] | Schwalm, J.; Gerstenmeyer, M.; Zanger, F. & Schulze, V. (2020), „Complementary Machining: Effect of tool types on tool wear and surface integrity of AISI 4140 “. Procedia CIRP 87, CIRP, S. 89-94. 10.1016/j.procir.2020.02.035 Abstract Complementary Machining is a process strategy for the time-efficient mechanical surface treatment of metallic workpieces. The characteristic of Complementary Machining is that after machining, a mechanical surface treatment is carried out using the cutting tool. The cutting tool moves over the workpiece surface in opposite direction to the machining process and induces an elastic-plastic deformation in the surface layer. Previous investigations have shown the possibility to achieve life-enhancing surface layer states in turning of AISI 4140 with Complementary Machining and to achieve fatigue strengths comparable to those after shot peening.

In this paper, the influence of the tool types and process parameters, such as the feed rate, on the resulting topography and the tool wear, represented by changes of cutting edge microgeometry, during Complementary Machining of AISI 4140 are investigated based on the previous investigations. In addition to different substrates of the cutting insert, the focus of the investigations is also on the influence of tool coating. Both the tool wear and the resulting topography were analyzed tactilely and correlated with the process parameters. The results show a clear influence of the used substrate of the cutting insert and coating on the tool wear and the resulting topography. |

|

| [2] | Schwalm, J.; Liu, Y.; Söllner, Y.; Gerstenmeyer, M.; Zanger, F. & Schulze, V. (2020), „Komplementärzerspanung - Zerspanung und mechanische Oberflächenbehandlung in einer Aufspannung“, wt Werkstattstechnik online, 10.37544/1436-4980-2020-11-12-7 Abstract In the manufacturing of highly stressed components, machining is often succeeded by a mechanical surface treatment in order to specifically modify surface layer conditions such as roughness or hardening. In the process of Complementary Machining, machining and mechanical surface treatment are performed in one clamping with the use of the tool. In the following, the potential of Complementary Machining when treating steel 42CrMo4 and aluminum alloy AlCuMgPb with regard to roughness is shown. |

.gif)